Page 32 - Mines and Minerals Reporter eMagazine - Volume October 2021

P. 32

TECHNOLOGY

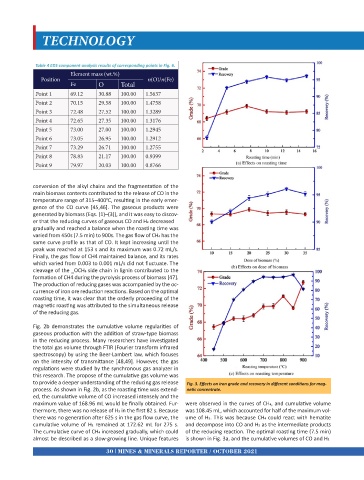

Table 4 EDS component analysis results of corresponding points in Fig. 6.

Element mass (wt.%)

Position n(O)/n(Fe)

Fe O Total

Point 1 69.12 30.88 100.00 1.5637

Point 2 70.15 29.58 100.00 1.4758

Point 3 72.48 27.52 100.00 1.3289

Point 4 72.65 27.35 100.00 1.3176

Point 5 73.00 27.00 100.00 1.2945

Point 6 73.05 26.95 100.00 1.2912

Point 7 73.29 26.71 100.00 1.2755

Point 8 78.83 21.17 100.00 0.9399

Point 9 79.97 20.03 100.00 0.8766

conversion of the alkyl chains and the fragmentation of the

main biomass contents contributed to the release of CO in the

temperature range of 315–400 C, resulting in the early emer-

0

gence of the CO curve [45,46]. The gaseous products were

generated by biomass (Eqs. (1)–(3)), and it was easy to discov-

er that the reducing curves of gaseous CO and H2 decreased

gradually and reached a balance when the roasting time was

varied from 450s (7.5 min) to 900s. The gas flow of CH4 has the

same curve profile as that of CO. It kept increasing until the

peak was reached at 153 s and its maximum was 0.72 mL/s.

Finally, the gas flow of CH4 maintained balance, and its rates

which varied from 0.003 to 0.001 mL/s did not fluctuate. The

cleavage of the _OCH3 side chain in lignin contributed to the

formation of CH4 during the pyrolysis process of biomass [47].

The production of reducing gases was accompanied by the oc-

currence of iron ore reduction reactions. Based on the optimal

roasting time, it was clear that the orderly proceeding of the

magnetic roasting was attributed to the simultaneous release

of the reducing gas.

Fig. 2b demonstrates the cumulative volume regularities of

gaseous production with the addition of straw-type biomass

in the reducing process. Many researchers have investigated

the total gas volume through FTIR (Fourier transform infrared

spectroscopy) by using the Beer-Lambert law, which focuses

on the intensity of transmittance [48,49]. However, the gas

regulations were studied by the synchronous gas analyzer in

this research. The propose of the cumulative gas volume was

to provide a deeper understanding of the reducing gas release Fig. 3. Effects on iron grade and recovery in different conditions for mag-

process. As shown in Fig. 2b, as the roasting time was extend- netic concentrate.

ed, the cumulative volume of CO increased intensely and the

maximum value of 168.96 mL would be finally obtained. Fur- were observed in the curves of CH4, and cumulative volume

thermore, there was no release of H2 in the first 82 s. Because was 108.45 mL, which accounted for half of the maximum vol-

there was no generation after 625 s in the gas flow curve, the ume of H2. This was because CH4 could react with hematite

cumulative volume of H2 remained at 172.62 mL for 275 s. and decompose into CO and H2 as the intermediate products

The cumulative curve of CH4 increased gradually, which could of the reducing reaction. The optimal roasting time (7.5 min)

almost be described as a slow-growing line. Unique features is shown in Fig. 3a, and the cumulative volumes of CO and H2

30 MINES & MINERALS REPORTER / OCTOBER 2021