Page 6 - Mines and Minerals Reporter eMagazine - Volume October 2021

P. 6

DIGITALISATION

cal modelling. At present level of tech-

nology available, e-Maintenance solu-

tions can carry out all the ordering of

the spareparts and manage work force

automatically thereby saving a lot of

time. Use of e-maintenance tools in the

future will push predictive health and

performance monitoring of machinery

into prescriptive maintenance deci-

sions. Figure 4 is an example of today's

vibration monitoring for maintenance

decision.

Web Services

Often the data measured by the devices

have to be stored in hardware specific

format. However, today's system aims

at establishing a standardized format

of datasets in order to make the inte-

gration of hardware and software for

maintenance more straightforward.

Machinery Information Management

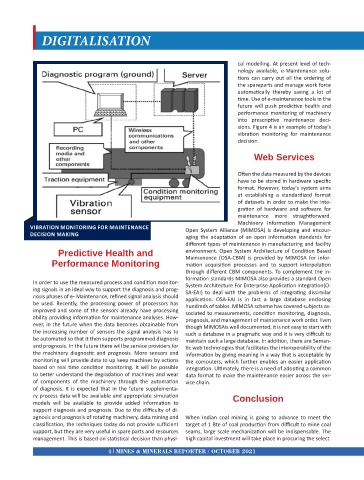

VIBRATION MONITORING FOR MAINTENANCE Open System Alliance (MIMOSA) is developing and encour-

DECISION MAKING aging the adaptation of an open information standards for

different types of maintenance in manufacturing and facility

Predictive Health and environment. Open System Architecture of Condition Based

Performance Monitoring Maintenance (OSA-CBM) is provided by MIMOSA for infor-

mation acquisition processes and to support interpolation

through different CBM components. To complement the in-

formation standards MIMOSA also provides a standard Open

In order to use the measured process and condition monitor- System Architecture For Enterprise Application Integration(O-

ing signals in an ideal way to support the diagnosis and prog- SA-EAI) to deal with the problems of integrating dissimilar

nosis phases of e- Maintenance, refined signal analysis should application. OSA-EAI is in fact a large database enclosing

be used. Recently, the processing power of processors has hundreds of tables. MIMOSA scheme has covered subjects as-

improved and some of the sensors already have processing sociated to measurements, condition monitoring, diagnosis,

ability providing information for maintenance analyses. How- prognosis, and management of maintenance work order. Even

ever, in the future when the data becomes obtainable from though MIMOSAis well documented, it is not easy to start with

the increasing number of sensors the signal analysis has to such a database in a pragmatic way and it is very difficult to

be automated so that it then supports programmed diagnosis maintain such a large database. In addition, there are Seman-

and prognosis. In the future there will be service providers for tic web technologies that facilitates the interoperability of the

the machinery diagnostic and prognosis. More sensors and information by giving meaning in a way that is acceptable by

monitoring will provide data to up keep machines by actions the computers, which further enables an easier application

based on real time condition monitoring. It will be possible integration. Ultimately, there is a need of adopting a common

to better understand the degradation of machines and wear data format to make the maintenance easier across the ser-

of components of the machinery through the automation vice chain.

of diagnosis. It is expected that in the future supplementa-

ry process data will be available and appropriate simulation Conclusion

models will be available to provide added information to

support diagnosis and prognosis. Due to the difficulty of di-

agnosis and prognosis of rotating machinery, data mining and When Indian coal mining is going to advance to meet the

classification, the techniques today do not provide sufficient target of 1 Bte of coal production from difficult to mine coal

support, but they are very useful in spare parts and resources seams, large scale mechanization will be indispensable. The

management. This is based on statistical decision than physi- high capital investment will take place in procuring the select

4 MINES & MINERALS REPORTER / OCTOBER 2021